PHOTOVOLTAIC SOLAR COOKING

WITHOUT BATTERIES

WITH PTC CERAMIC HEATERS

General summary of the documentation:

- Home

- Presentation of the cooker

- Design of the cooker

- 1 - Building and using a cooker

- 2 - Building a cooker: appendices

- 3 - Theoretical presentations

- 4 - Technical information

- 5 - Photovoltaic panel supports

- 6 - Automation of PTC ceramics

- 7 - Photovoltaic solar water heater

- 8 - Library

- Who are we?

the parts shown in grey are still under construction.

DESIGN OF THE COOKER

The architecture of the cooker is entirely underpinned by the use of ceramic resistors, with multiple consequences.

- A) Lower prices for photovoltaic panels

- B) PTC ceramic resistors

- C) Ceramics and electricity

- D) Ceramics and lower costs

- E) Céramiques et thermique

- F) Céramiques et conduite du capteur

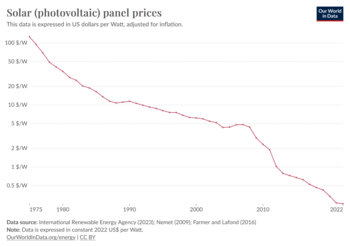

A) The fall in the price of photovoltaic panels

The drastic fall in the price of photovoltaic electricity has made possible what

would have been unthinkable in the last century: using photovoltaic energy

to produce thermal energy.

B) PTC ceramic resistors

Like all resistors, ceramic material produces heat when an electric current is

passed through it. But as it heats up, its electrical resistance decreases, and

at 200°C it is divided by three compared with the ambient temperature, so its

heating power is multiplied by three. Then, above 200°C, resistance rises sharply

until it becomes very high, so the electric current can no longer flow, and heat

production stagnates.

Although little known to the general public, ceramic resistors are very

common in everyday life. For example: small ceramic heaters, available in all

household electrical goods stores and sold as auxiliary heaters, are a good

example. Small and light, they must be fitted with a fan that continuously

expels the calories produced by the ceramic, otherwise the heat production

would stagnate.

Although little known to the general public, ceramic resistors are very

common in everyday life. For example: small ceramic heaters, available in all

household electrical goods stores and sold as auxiliary heaters, are a good

example. Small and light, they must be fitted with a fan that continuously

expels the calories produced by the ceramic, otherwise the heat production

would stagnate.

The characteristics of ceramic heating elements are very interesting for our cooker:

- there is no risk of the heating elements burning out.

- a temperature of 200° is more than enough for all boiling, braising, steaming, etc.,

with the exception of cooking in oil and grilling.

- 200° is lower than the ignition temperature of cotton.

C) Ceramics and electricity

The usual electrical resistors (electric hobs, heaters, toasters, etc.) are designed

to operate at a well-defined electrical voltage (= "Voltage"), supplied by the mains,

for example 230 Volt, plus or minus small variations that are technically permissible

but transparent to the user. The laws of electricity teach us that, in the event

of a significant drop in voltage, heat production collapses, and that in the event

of too great an increase in voltage ("overvoltage") the resistor is destroyed,

it burns out.

Given that all conventional electrical equipment only works on a correctly

regulated voltage, all photovoltaic installations need to regulate the electrical

current using a battery flanked by a charge regulator at the input and an

inverter at the output.

Ceramic resistors can withstand significant variations in current without

the risk of burn-out.

The ceramic resistors used for the cooker operate at a voltage of 25 to 40 volts,

corresponding directly to the current produced by a photovoltaic panel,

and which remains below the safety threshold for direct current, set by

regulations at 48 volts. So users are safe.

D) Ceramics and lower overall cooker costs

All other things being equal (industrial mass production, etc.), a ceramic cooker

is not intrinsically much more expensive than an ordinary electric cooker.

The main advantage in terms of cost comes from the absence of a battery

and its two power regulation acolytes. In a "conventional" solar electric

cooking system, it is the battery that is the most expensive, the most fragile,

the most polluting and the most dangerous component (see part 8, "Library").

Removing the battery could be the decisive factor in converting to solar

electric cooking.

But the ceramic cooker works very well on battery power. And when the

battery dies, the cooker will still be able to run on solar power.

E) Ceramics and heat

The maximum temperature of ceramics, around 200 to 220°C, is lower than

the ignition temperature of cotton. It is therefore possible to insulate the

whole device, heating block and container, for example with cotton towels,

or similar. This significantly improves the efficiency of the cooker, and

relatively lowers the overall cost of the installation per unit of energy

produced: "efficiencies are multiplicative (and so are losses...)".

You can also choose not to insulate, just add solar panels.

Insulation can also be used in the event of temporary cloud cover, in which

ase the cooker continues to operate as a Norwegian kettle. And depending

on the food to be cooked, it is possible to work alternately with two cookers

on a single sensor: one cooker rises in temperature while the other continues

cooking under insulation, and vice versa.

F) Ceramics and operating the cooker

The output of a photovoltaic collector depends on the amount of sunlight

it receives, but also (and this is not intuitive!) on the load applied to it.

Fortunately, ceramic resistors have a wide operating range. In the event

of significant variations in sunshine, the number of ceramic elements in

operation needs to be modified, and to get closer to the optimum the driver

has a small voltmeter at his disposal.

If the weather is fine, the driver can choose the number of resistors in

operation and go about his business.

If the aim is to produce hot water in a water heater as described in Part 7,

intended to operate throughout the day, the installation can be automated

using a micro-controller of the Arduino or other type.