PHOTOVOLTAIC SOLAR COOKING

WITHOUT BATTERIES

WITH PTC CERAMIC HEATERS

General summary of the documentation:

- Home

- Presentation of the cooker

- Design of the cooker

- 1 - Building and using a cooker

- 2 - Building a cooker: appendices

- 3 - Theoretical presentations

- 4 - Technical information

- 5 - Photovoltaic panel supports

- 6 - Automation of PTC ceramics

- 7 - Photovoltaic solar water heater

- 8 - Library

- Who are we?

the parts shown in grey are still under construction.

The aim is to provide additional information for the layman. By design, this photovoltaic solar cooker is intended for self-builders. Experienced professionals, craftsmen or technicians manufacturing cookers with a view to marketing, will kindly bear with the abundance of details given below...

We are talking here about a cooker operating with a panel of 375 W

max / 40V max / 10 A max, but all other cooker power ratings are

conceivable provided that all the rules of the art are respected,

particularly with regard to the electrical characteristics of the

various components, and provided that, for safety reasons, they

do not exceed 40 Volt.

The fourth part is devoted to more general information on electricity,

components, the photovoltaic panel, etc.

The web links listed below are commercial links provided for information

only, and their continuity is not guaranteed; however, these products

are commonly used.

A) The cooker base

Exterior grade plywood is made with moisture-resistant glue, so it's a good choice for the cooker. 8 mm plywood is easy to cut with a fine-toothed hand-saw. It is advisable to always mark the cut with two lines to make it clear where the cut is to be made, and to specify which side of the cut the waste is on.

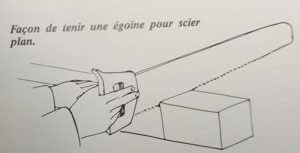

To prevent the egoinic saw from stubbornly deviating from the

line assigned to it, "Leave the index and middle fingers extended,

so as to keep the blade and forearm in the same axis" (Xavier Buhot-Launay

- "Construire un bateau en bois"; a model of pedagogy ! ).

All plywood must be painted or stained.

After pre-assembling for test purposes, if possible, use glued and

screwed joints. 3x20 screws work very well. To assemble a piece

of plywood on a wooden cleat, it is always preferable to drill the

plywood beforehand (diameter 2 or 2.5 for a 3 mm screw), and

to countersink the location of the screw head with a 90° countersink.

B) The control panel

To supply the thin sheets that will hold the console components, all solutions are acceptable. You can also supply PVC sheet, for example from Polydis.fr, sheet thickness 3 mm code PVCC3W04..

To make the cuts, you can use a Bahco 302 scroll saw, ref 63813414

at Leroy Merlin. A DIY cutter can be used for finishing if required.

Alternatively, you can machine the sheet using a small table-top

CNC machine, or make the parts on a 3D printer.

It is preferable to supply the electrical components (switches, etc.)

before making the cuts, because of the possible changes in dimensions.

N.B. If you have any problems with the supply or manufacture of

small, thin plates for a one-off build, you may contact

contact@cuisson-solaire-photovoltaique.org.

supply of switches

Good quality switches are essential for two reasons. Firstly, in

the case of the photovoltaic cooker, the current intensity, also

known as amperage, is relatively high, up to 8 or 10 Ampere

(while the voltage does not exceed 35 or 40 volts). To transmit

this amount of electricity, it's essential that the switches have

good contacts, otherwise they heat up (which consumes

electricity ! ) and can be destroyed by heat, not to mention the

risk of fire.

Secondly, we're talking about direct current (DC) here, not

alternating current (AC) as is usually available on electricity

networks. One of the peculiarities of direct current is that

it causes a flash when a circuit is broken, when the current

is 'cut', resulting in premature wear and tear of the contacts.

Any switch that heats up should be eliminated. Switches

available on the Net at very low prices should be rejected.

Resistor control switches with two "2 x Off/On" positions, panel cut-out 19.2 x 13 mm,

clip terminals 4.8 mm: for example from Conrad.fr, ref. 1587538 - 62 or 1587540 - 62 .

The "2 x Off/On" specification is important, in order to duplicate the power supply

circuit and therefore reduce the flash.

Resistor control switches with two "2 x Off/On" positions, panel cut-out 19.2 x 13 mm,

clip terminals 4.8 mm: for example from Conrad.fr, ref. 1587538 - 62 or 1587540 - 62 .

The "2 x Off/On" specification is important, in order to duplicate the power supply

circuit and therefore reduce the flash.

Wattmeter supply.

On an Asian website, search for "wattmeter 0-20 A, 6.5-100 V DC", or directly

with the reference PZEM-031.

The cooker operator only takes into account the power in Watt to adapt the

number of ceramics in operation, taking into account the sunshine at the time.

The cooker operator only takes into account the power in Watt to adapt the

number of ceramics in operation, taking into account the sunshine at the time.

Console wiring.

Use flexible cable according to the H07V-K standard. The K specifies

that it is a flexible cable, a U would indicate that it is a rigid cable, unsuitable

for our use. Regarding the soldering of electrical cables, many tutorials are

available on the Net.

Electrical connections can be crimped or soldered (or both!). Isolate

connections with of the heat-shrink tubing; after installing a small piece

of sheath on the weld, just heat it slightly with a lighter.

C) The heating block

Aluminium sheet.

5 mm thick, which is a good compromise between heat transfer and

rigidity, is essential.

If the sheet is sheared, make sure that it is not bent very slightly,

which would make it unsuitable for our use. If you're lucky, you

may find a sheet of suitable dimensions from a scrap dealer on

the Internet, in which case a jigsaw cut is perfectly feasible (make

sure there's no vibration on the saw), and the 142 mm diameter

doesn't have to be perfectly rounded.

A good solution is to go to a laser or water jet cutting workshop,

but these workshops don't usually handle such small quantities.

Drilling

To mark out the holes, you can use this template in A4-.pdf format.

Download it here, look for it in your downloads, and print it.

Download .

Check the dimensions with the two 100 mm lines. Then

fix the template to the heating plate, and drill directly through

the paper with the centring drill.

If you have a CNC machine at your disposal, download

the plan in DXF format here (it will appear in your downloads)

drawing DXF

With a small desktop CNC, it's very easy to "point"

the holes before drilling them again.

N.B. If you have any problems with the supply of aluminium sheet

for a one-off project, you may contact

contact@cuisson-solaire-photovoltaique.org.

Once the drilling, milling and deburring have been completed, carry out two checks

- a visual check: place a ruler on the plate and use a light to check that

there are no gaps between the plate and the ruler.

- a tactile check, by running your fingertip over the entire surface to spot any burrs.

Some thermal considerations

The thermal conduction λ of aluminium, i.e. its capacity to allow heat to pass

through the material, is 230 W/m.K. The thermal conduction λ of air at 100°C

is 0.031 W/m.K. Whatever the units here, the ratio is 230/0.031, or 1:7420.

A layer of still air 1 millimetre thick insulates as much as ... 7.40 metres of

aluminium. This shows just how important the flatness, good surface finish

and cleanliness of the hotplate are for the transfer of heat between the

hotplate and the cooking vessel: the slightest air gap compromises the

operation of the cooker. (For the sake of completeness, it should be pointed

out that air can also transmit heat, but in this case we are talking about

masses of moving air, convection and not conduction through the material,

which is not the case here).

Fixing the ceramics and assembling the heating block

- Belleville spring washers: obtain washers with a diameter of 4.2 inside and 8 outside. See for example: otelo.com 67881793, or vis-express.fr 3552170051 (available in quantities of 30)

- banana plugs, for example Radiospare ref. 175-8974 , can be used to connect the cooker to the solar collector, replacing the domino.

For the supply of PTC ceramics, please refer to Part 4.